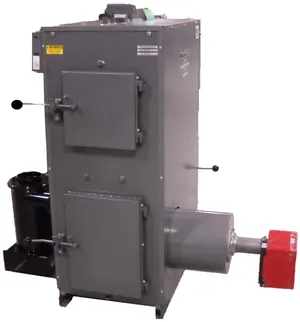

Our lineup of Indoor Wood Boilers, the Wood Gun, burns 66% less wood than a traditional wood furnace. Utilizing the latest technology, our wood gasification boilers are efficient and built to outlast! For more information about these models, scroll down or click the 'More Details' button above.

* Commercial only per EPA requirements

Manufactured Since 1981

The Wood Gun series of indoor wood boilers has been manufactured for over 40 years. Our small team here in Pennsylvania takes pride in making high-quality wood boilers, each made to the ASME and UL standards.

Best Warranty

The E100-E250 and the residential Wood Gun boilers use ¼" thick Type 304 stainless steel in the construction of the firebox, heat exchanger, and door frames. We use Type 304 stainless steel for its unsurpassed quality and longevity. Our stainless-steel boilers show no signs of deterioration, even after well over 35 years of service. This is why we gave these wood boiler vessels a 20-year warranty, with the first ten years being completely covered for both labor and materials! We stand behind our products and trust our team who builds them!

For the E500 & E1000, our larger commercial wood boilers, we use type-304 stainless steel in the firebox where corrosion normally takes place. We then use SA-36 steel in the heat exchanger to better handle the extreme heat produced by these monster units. Corrosion is not an issue in the heat exchanger thanks to the wood gasification technology.

Wood Gasification

These wood furnaces harness all the power wood can provide. Gasification is a big word that means the capture and burning of wood gas, aka smoke. Smoke and creosote are unburnt fuel; not to mention, they pose a risk for fire and your health. These wood furnaces completely burn the smoke and creosote. Our units are a downdraft gasification boiler.

True Downdraft Boiler

The Wood Guns operate differently from a traditional wood stove or furnace. Traditionally, the fire burns up from the bottom. Our wood gasification boilers have a specially designed firebox. The floor is made of refractory (firebrick). The fire is pulled down through the "floor" into the combustion chamber by our signature draft fan. This firebox inverts the flame, burning the wood upside down, which is why we refer to it as a "downdraft boiler". An intense flame is created, reaching temperatures of 2,000°F.

With the correct air/fuel ratio, this intense flame allows us to capture up to 60% more of the energy found in wood, and completely burn all smoke, eliminating creosote and all the problems that come with it.

Smoke

The Wood Gun™ wood gasification boiler, when installed, maintained, and operated properly, produces no visible smoke and prevents creosote formation in the chimney.

Cut Wood Usage in Half

The Wood Gun line is one of the most fuel-efficient wood boilers. By completely burning the smoke and creosote, we utilize more of the wood's available energy instead of sending it up the flue. This means you will cut less wood, stack less wood, and load less wood. It sounds like a win, win, win.

Type and Moisture of Wood

The firebox of our indoor wood boiler accommodates wood sizes ranging from unsplit logs to full rounds up to 10″. Typically, you only need to load the large firebox 2-3 times daily.

The Wood Gun™ will handle wood of relatively high moisture content, as high as 29% moisture, freeing you from curing a 12–18-month supply of wood. Unlike European-style wood gasifiers, our indoor wood boiler excels on full rounds of firewood.

The Wood Gun™ will burn all types and species of wood, even softwood. However, if you are burning 100% softwood species, we would recommend our secondary air option if your unit does not come equipped with that.

Swirl Chamber

Another amazing innovation our wood boilers use is our signature heat exchanger called the Swirl Chamber. The swirl chamber is upwards of 85% efficient. Again thanks to our signature draft fan, the Swirl Chamber cleans itself using the high-velocity air and fly ash. The scrubbing action allows maintenance to be needed only once per season. In this small area, we can decrease the 2,000°F exhaust temperature down to about 350°F!

Stack Temperature

Exhaust stack temperature is one indicator of transfer efficiency. During combustion, temperatures reach around 2000° Fahrenheit. Amazingly, our exhaust stack temperature ranges from about 260-300° Fahrenheit. This stack temperature is unheard of in the industry. The Alternate Heating Systems Wood Gun™ is truly the pinnacle of wood-fueled heating devices!

Off-Cycle

The Wood Gun cycles on and off much like an oil or gas-fired boiler. All of the doors and the automatic air intake are sealed with gaskets. Therefore, during the off-cycle, air does not enter the boiler. This causes the flame to go out quickly and combustion to stop. Without flame, the boiler cannot make more heat, so overheating is never an issue. When air is allowed back into the wood chamber, the huge, superheated refractory immediately rekindles the fire, and the Wood Gun starts generating heat again.

Optional Fuel Backup

The Wood Gun can be equipped with a backup system. You can select from fuel oil, propane, or natural gas. The burner mounts to the wood boiler and fires into the swirl chamber. This eliminates the need for a second appliance, a second chimney, and all the piping that goes with it.

It ensures consistent warmth by being available when wood is not or is unable to be reloaded, minimizing downtime. This system enhances energy security and allows for more flexible fuel sourcing, offering peace of mind and ensuring comfort throughout the heating season.

Automatic switchover is only available for Fuel Oil. E500 and E1000 cannot be equipped with a backup system.

Thermal Storage

The Wood Gun boilers do not require a thermal storage system. However, thermal storage offers several benefits, including reduced emissions and increased efficiency during periods of low heating demand.

The main benefit and reason many European gasification boilers require thermal storage is to reduce the amount of firebox condensate and to lengthen the boiler's lifespan. However, over our many years of experience, we have seen boilers with thermal storage fail prematurely and realize that the cost to install a complex system can be breathtaking.

We have found that the firebox condensate and creosote can not corrode the 304 stainless steel. By using better material, we save installation costs and give peace of mind for decades. The Wood Gun’s use of 304 stainless steel allows us to offer a 20-year warranty, including coverage for corrosion, regardless of whether you use thermal storage or not.

The main advantages of not requiring thermal storage include:

- Cost savings: Thermal storage systems can cost thousands of dollars.

- Simpler installation and operation: Without thermal storage, the system is easier to install and operate.

- Space savings: Eliminating thermal storage reduces the overall footprint of the installation.

After 40 years of history, we have created the Super Wood Gun series. These indoor wood gasification boilers are overengineered for longevity and built with high-grade 304 Stainless steel. This new generation of wood boiler is more efficient and burns cleaner than the original. The Super Wood Gun was built to exceed the new federal emission laws for residential wood boilers. We currently have three models in this series: the Super E110, the Super E210, and the Super E210 Outdoor.