The E500 is a commercial wood gasification boiler. It is available in carbon steel or stainless steel and can heat up to 20,000 square feet. It has been manufactured in Pennsylvania since 1981. This model is commonly used with our automatic self-loading equipment. Self-loading wood boilers are the best way to utilize the cost-effectiveness of wood in larger applications!

The Wood Gun series of boilers is one of the most fuel-effective choices available. While standard boilers waste two-thirds of a fuel’s energy potential, the E500 Wood Gun catches and utilizes 66% more burning matter, converting it all into clean, consistent heat.

- Industry's best warranty

- True Downdraft Gasification

- Cut wood usage in half

- No Smoke or Creosote

- High-efficiency Swirl Chamber

- Optional Fuel Backup

- Thermal Storage not required

- Commercial Only

- Pressureized Vessel

- 1/4" thick Type-304 Stainless Steel

- Made in Pennsylvania

- Family-owned Company

The Wood Gun series can be utilized with any heating system (water-based, steam, forced-air).

The E500 can be ordered with the equipment to make it a self-loading wood boiler, which enables you to heat an assortment of wood particle fuels, varying from sawdust and wood chips to shavings, pellets, and other wood wastes¹. Additionally, with an AHS automatic feed system, if you want to use logwood in the unit, you can change the firebox slightly to accept logwood; it takes about 15 minutes.

How it functions

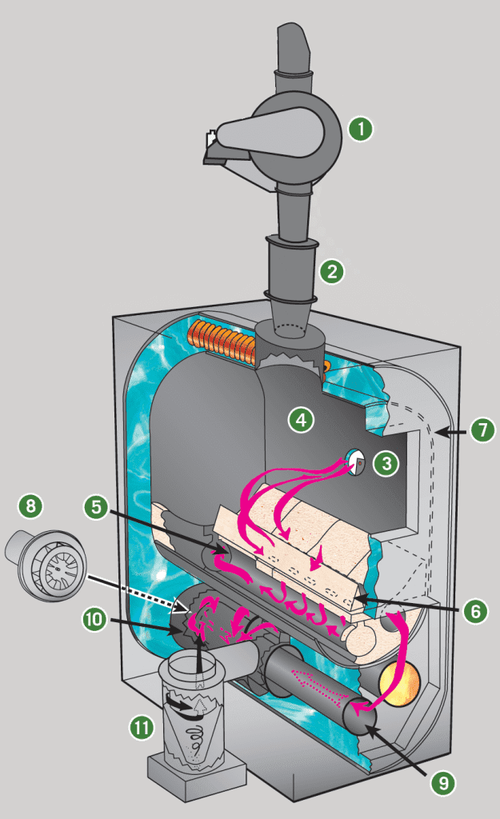

The E500, as a self-loading wood boiler, can use an assortment of fuels. For example, we can burn soft or hardwoods with moisture ranging from 5% to 40%. We can accommodate sawdust, chips, or mulch. In a typical setting, particle fuel is transported by a blower or other ways to a large storage bin. From there, the fuel is transported on request through an auger and a bin agitator, which discharges material uniformly. A photoelectric sensor (3) supervises the height of the fuel in the fuel chamber (4) and turns on the feed system when more fuel is needed in the firebox.

Two main safety features of the AHS self-loading wood boilers are the rotary air-lock (1) and the fuel valve (2). It is essential to regulate the airflow through the gasification boiler system to control burning and permit off cycle. It is vital that no air penetrates into the boiler from the top feed opening. This is achieved using a rotary valve, a device that utilizes the same concept as a department store’s spinning door. The fuel valve is a device that separates the fuel that is being burned in the fuel chamber and the fuel that is in the loading system, preventing the ignition of the fuel in the loading system.

The Wood Gun combustion chamber (5) is situated below the fuel chamber and is comprised of cast refractory sections, which are placed end to end to make up the three tunnels. This material has properties and texture similar to firebrick and helps to create the environment needed to achieve the high temperatures required for clean combustion. Slots in the refractory bricks provide passageways from the fuel chamber to the combustion chamber. Smaller fuel particles are prevented from falling through the slots by a fuel diversion structure (6). A variety of shapes and sizes of fuel diverter blocks are available based on the size and kind of fuel.

Once the gas is released during the gasification process, it will be drawn toward the fuel diverter and through the slots in the combustion chamber, where temperatures in excess of 2000° F are attained. The powerful heat generated here spreads through the refractory lining (7) in the lower portion of the fuel chamber, evaporating water from the fuel and allowing it to gasify (pyrolysis).

In order to draw the gases into the combustion chamber, a draft-inducing fan (8) is used. The fuel can effectively burn upside down due to the negative pressure. This is important because it allows fuel to be loaded continuously without extinguishing the fire. Once the gases are drawn into the combustion chamber, they pass through the firetubes (9), where most of the heat exchange takes place. On small-scale Wood Guns like the one shown, only one firetube is present. Multiple firetubes are used to increase the surface area available for heat exchange in the larger models. After the firetubes, the gases are given a swirling action as they pass through the swirl chamber (10) and into the cyclone ash separator (11). Here, ash is removed from the exhaust air and deposited for easy disposal. Due to the unique design of the swirl chamber, the swirling motion scrubs the inner chambers, preventing much of the ash buildup that could decrease efficiency. Exhaust air then exits through the top of the cyclone ash collector into the flue, which has cooled to about 350 F.

The E500 has seals on all doors and on the automatic intake damper (air valve). During off-cycle, the air valve (s) close and completely eliminate air from entering the firebox. The fire soon goes out due to a lack of air. Thanks to our huge superheated refractory mass, the fire reignites immediately after off-cycle when oxygen is reintroduced to the system. By operating in this fashion, we do not waste any fuel when it is not needed.

¹An assortment of fuels can be heated, such as maize, nutshells, cherry seeds, and paper pellets. Fuel sources are restricted only by natural concerns, like the amount of soot produced, and fuel economy concerns, like accessibility and BTUs per pound.

BTU/hr

500,000

Typical Heating Capacity (square ft)

20,000

Weight (lbs)

4,500

Flue Size (in)

10

Fuel Type

Soft, Hard Logwood*, Biomass*

Optional Backup Fuel

N/A

Standard Door Opening (in)

18x18

Firebox Capacity (cubic ft)

28

Firebox Length (in)

54

Approximate Water Capacity (gal)

210

Width (cyclone removed) (in)

34

Height (in)

90

Depth (in)

72

Electric Requirements

220V, 60Hz, 20Amp

Domestic Coil

This Domestic Coil features a 100° F rise at 5 gallons per minute, 50° water inlet temperature, and 65 PSI water pressure. It is threaded into a 4 IN NPT threaded fitting provided on the boiler for this purpose.